2020 官网升级中!现在您访问官网的浏览器设备分辨率宽度低于1280px

请使用高分辨率宽度访问。

CMT (Cold Metal Transition Deposition Technology) additive manufacturing is a new type of wire arc additive technology, which has the characteristics of forming complex parts in one go and can achieve free manufacturing of parts. CMT welding technology is a new deposition process developed by Austrian company Fronius, which has the characteristics of high deposition rate, low heat input, precise arc length control, and no spatter. CMT deposition technology mainly uses external mechanical withdrawal force to promote short circuit transition of molten droplets, while improving the waveform of voltage and current. During short circuit transition, the current is almost zero, greatly limiting the welding heat input. CMT deposition digitally coordinates the wire feeding and withdrawal movements with the droplet transition process.

Surface melting deposition of membrane wall in garbage incinerator

corrosion mechanism

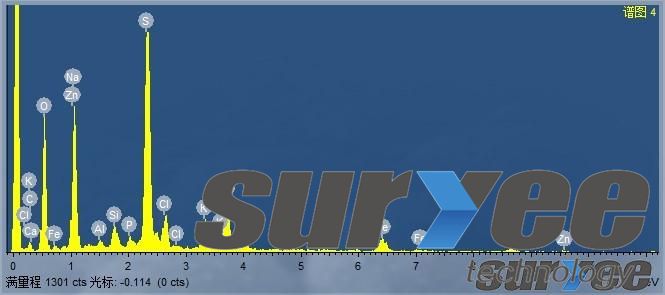

The garbage incineration boiler uses garbage as fuel, and the heat obtained from its combustion is used for heating or power generation, making garbage energy efficient. Due to the complexity and heterogeneity of garbage components, various highly corrosive media, mainly chlorides and sulfides, are generated during the incineration process. Before starting any project, our company recommends that the owner provide the corresponding burst pipe location for us to make a first-hand analysis report based on the corrosion components of the garbage. Currently, Saiyi Technology has conducted specific research on the corrosion components of garbage in several cities such as Guangzhou, Suzhou, and Foshan. For example, in a certain garbage power plant in Suzhou, the corrosive ash deposition is mainly composed of chloride salts (NaCl), while in a garbage power plant in Foshan, the content of sulfates (mainly potassium and calcium) is higher than that of chloride salts. It is worth mentioning that the heavy metal chloride PbCl2 appears in the corrosive components of Foshan garbage, with a melting point of 498 degrees. The presence of this substance undoubtedly reduces the melting point of salt deposition on the surface of the pipe. In response to this personalized situation, after joint discussions between our technical experts and experts from the Corrosion Center of Beijing University of Science and Technology, we have also provided an optimized anti-corrosion plan.

Most waste incineration power plants mainly contain corrosive substances such as sulfur, chlorine, sodium, potassium, and calcium, as shown in the following figure:

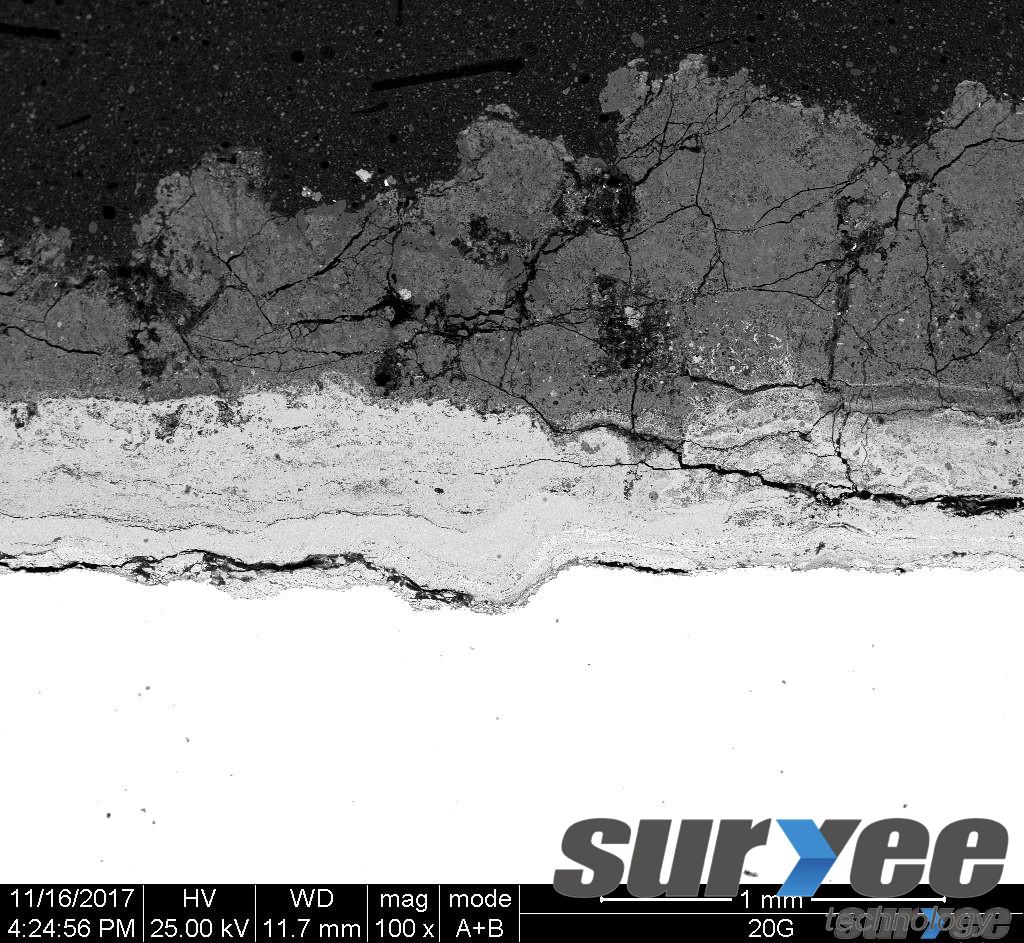

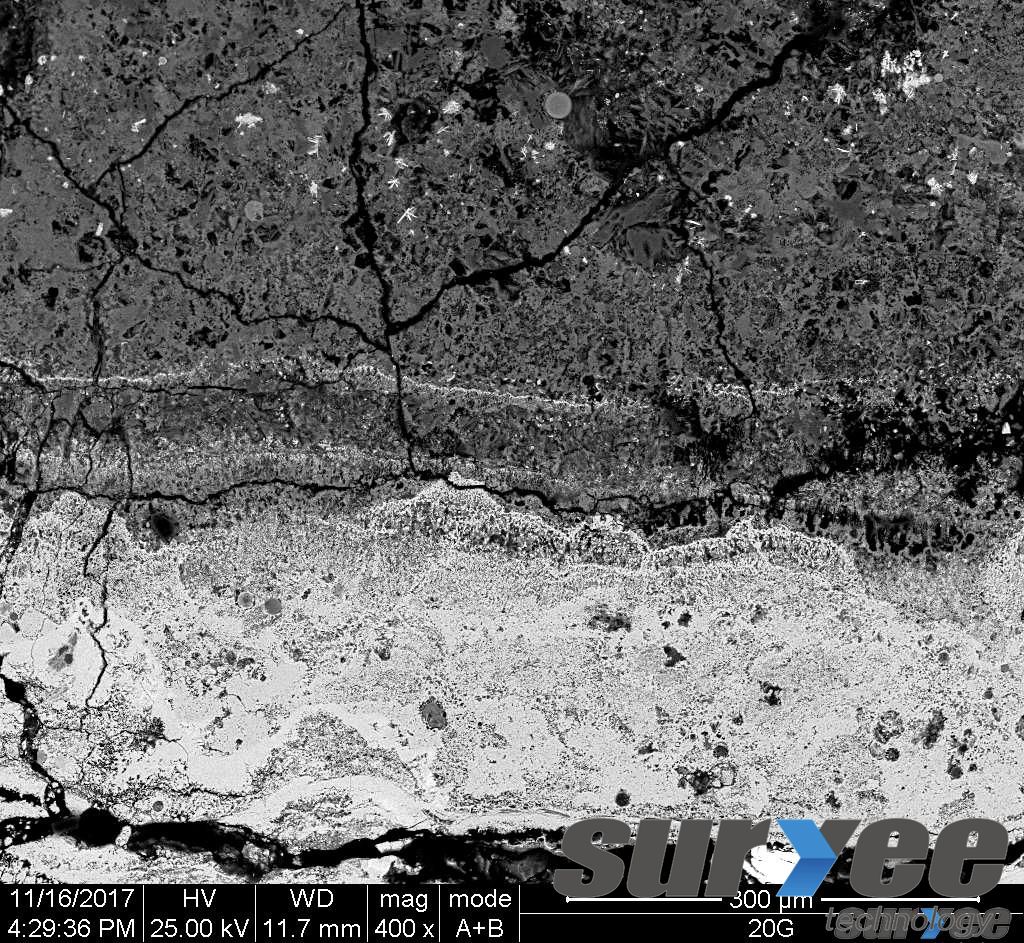

These low melting point ash deposition salts of metal chlorides undergo oxidation-reduction reactions with the oxide film on the metal surface, corroding the substrate; In addition, it will also co deposit with other inorganic salts in the flue gas on the metal surface, forming low melting point eutectic crystals, greatly reducing the melting point of the accumulated ash. A molten corrosive salt will be generated on the high-temperature pipe wall, forming a local liquid phase at the interface between the accumulated ash and metal, forming an electrochemical corrosion atmosphere. The base metal undergoes anodic dissolution, and the two oxidants O2 and Cl2 in the atmosphere are reduced. The base metal is further oxidized and combined with O2- to deposit in the form of loose oxide particles, or combined with Cl - to form chlorides. As corrosion progresses, a loose outer oxide film is formed on the outer surface of the molten chlorides, as shown in the following figure:

Due to the high diffusion rate of metal ions in molten salt, this electrochemical process seriously erodes the metal components of the boiler's water-cooled wall, superheater, and other parts, leading to premature performance degradation, as shown in the following figure:

The entire corrosion mechanism is represented by the chemical formula as follows:

2ZnCl2+2Fe2O3+O2=2ZnFe2O4+2Cl2

2ZnCl2+2Cr2O3+O2=2ZnCr2O4+2Cl2

ZnCl2+1/2O2=ZnO+Cl2

2Fe+3Cl2=2FeCl3

2Cr+3Cl2=2CrCl3

2FeCl3+3/2O2=Fe2O3+3Cl2

2CrCl3+3/2O2=Cr2O3+3Cl2

2MCl+SO3+H2O=M2SO4+2HCl

2NaCl+SO3+O2=Na2SO4+Cl2

As Cl ions continue to replenish, the corrosion reaction continues, and the simultaneous presence of sulfides accelerates the entire corrosion rate. Corrosion is a complex process involving multiphase interactions of gas, liquid, and solid. However, after a period of boiler operation, the surface of the pipe wall will be covered by accumulated dust. On the one hand, the accumulated dust will separate some of the gas and directly react with the pipe wall. On the other hand, the corrosive medium in the gas will react with the accumulated dust, and then the accumulated dust will react with the pipe wall. The entire conduction process forms a complete corrosion chain. This corrosion has become a limiting factor for further improving the conversion efficiency of waste to electricity and heat, seriously affecting the safe operation of waste incineration boilers.

Surface deposition of four tubes in a coal powder furnace

The deposition standard shall be executed in accordance with the Technical Specification for Anti Wear Spray Coating of Heating Surface of Circulating Fluidized Bed Boilers - DL/T 1595-2016. The welding process needs to ensure that the base material of the pipe does not undergo any material changes, does not generate stress, and the pipeline does not deform. The fusion alloy layer is tightly bonded with the base material of the pipe, with a fusion thickness of generally 1.5-2.5mm. It is necessary to ensure that there is no delamination, detachment, good heat conduction, smooth surface, and no ash hanging at high temperatures. After melting, the pipe has good wear resistance, high-speed erosion resistance, and resistance to cold and heat shock. The minimum hardness of the surface alloy layer after fusion reaches HRC40-50. When the operating temperature in the furnace is between 850 ℃ and 1000 ℃, the fusion layer does not oxidize, delaminate, and the material does not change. The surface of the deposited layer should be uniform and fully covered, without any leakage or exposure of the base material; There must be no group holes or deep pits, and repairs must be carried out when group holes or deep pits appear; No peeling, bulging, coarse particles, chipping, or other defects that affect the use of the coating are allowed. The upper transition area of the fusion layer needs to be polished and repaired, and the height of the transition area should not be less than 60mm. According to the current normal operating conditions, the service life of the deposited layer needs to ensure that there is no occurrence of base material wear, leakage, or pipe explosion in the water-cooled wall pipe wear area for 5 years.